The success or failure of an organization often depends upon two major factors: the quality of its product and meeting the customers’ delivery schedule.

Customers throughout the world are continually applying stringent criteria to quality policies in order to guarantee superior products and timely delivery.

Airborne is committed to work in accordance with the latest requirements of AS9100D and ISO 9001:2015 and routinely evaluates its practices. Our Quality Manual is available to our customers upon request.

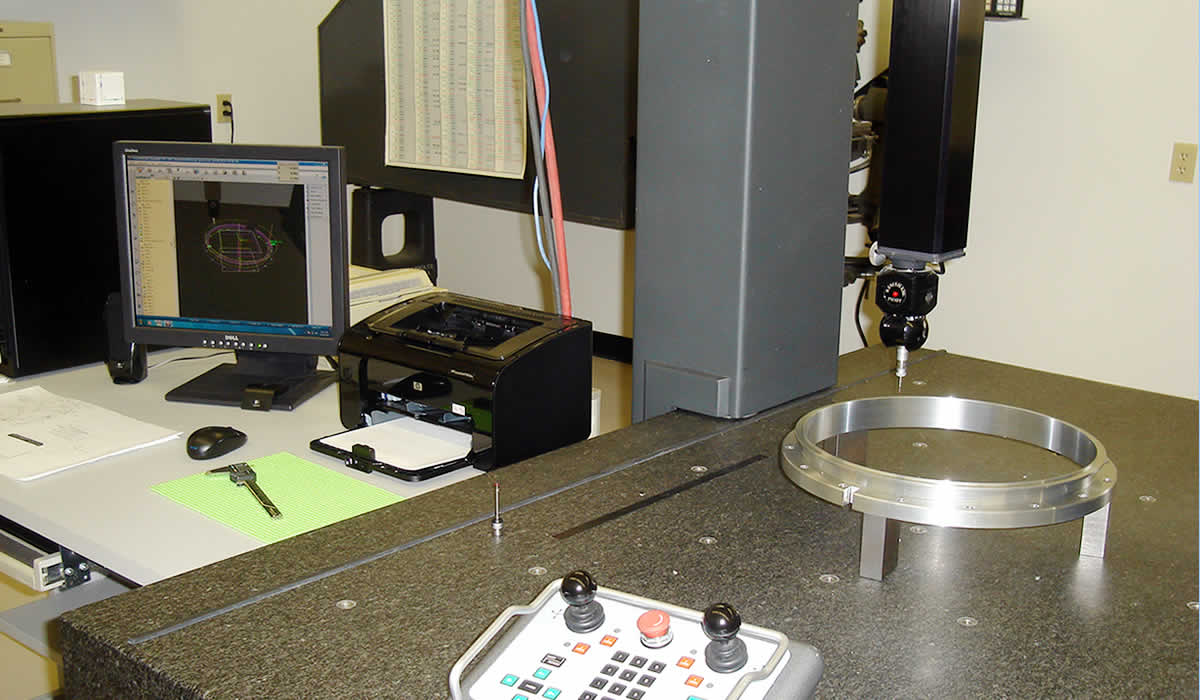

We have a self-contained Inspection Department with temperature and humidity monitoring. All measurement and test equipment is calibrated and maintained according to NIST and recorded on a computerized gage calibration and recall system.

For a copy of our QAPC, Click Here.

Our list of inspection equipment include an automated Brown and Sharp XCEL 7-10-7 Coordinate Measuring Machine (CMM), master gage blocks, Starrett Supermic, Rockwell Hardness Tester, surface comparison gage, numerous sets of dial bore gages, ring gages, thread gages, micrometers, calipers and many other precision inspection instruments.